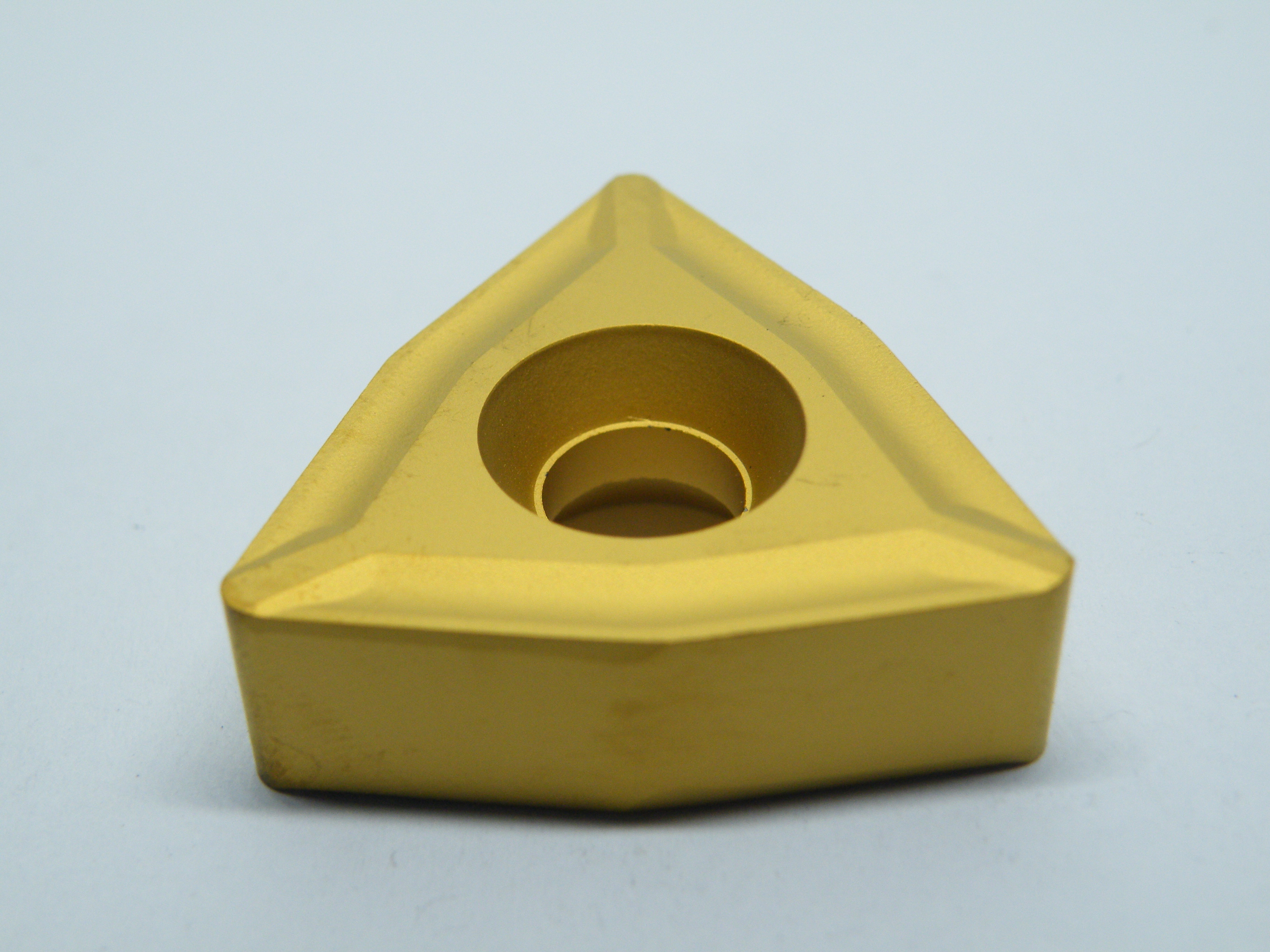

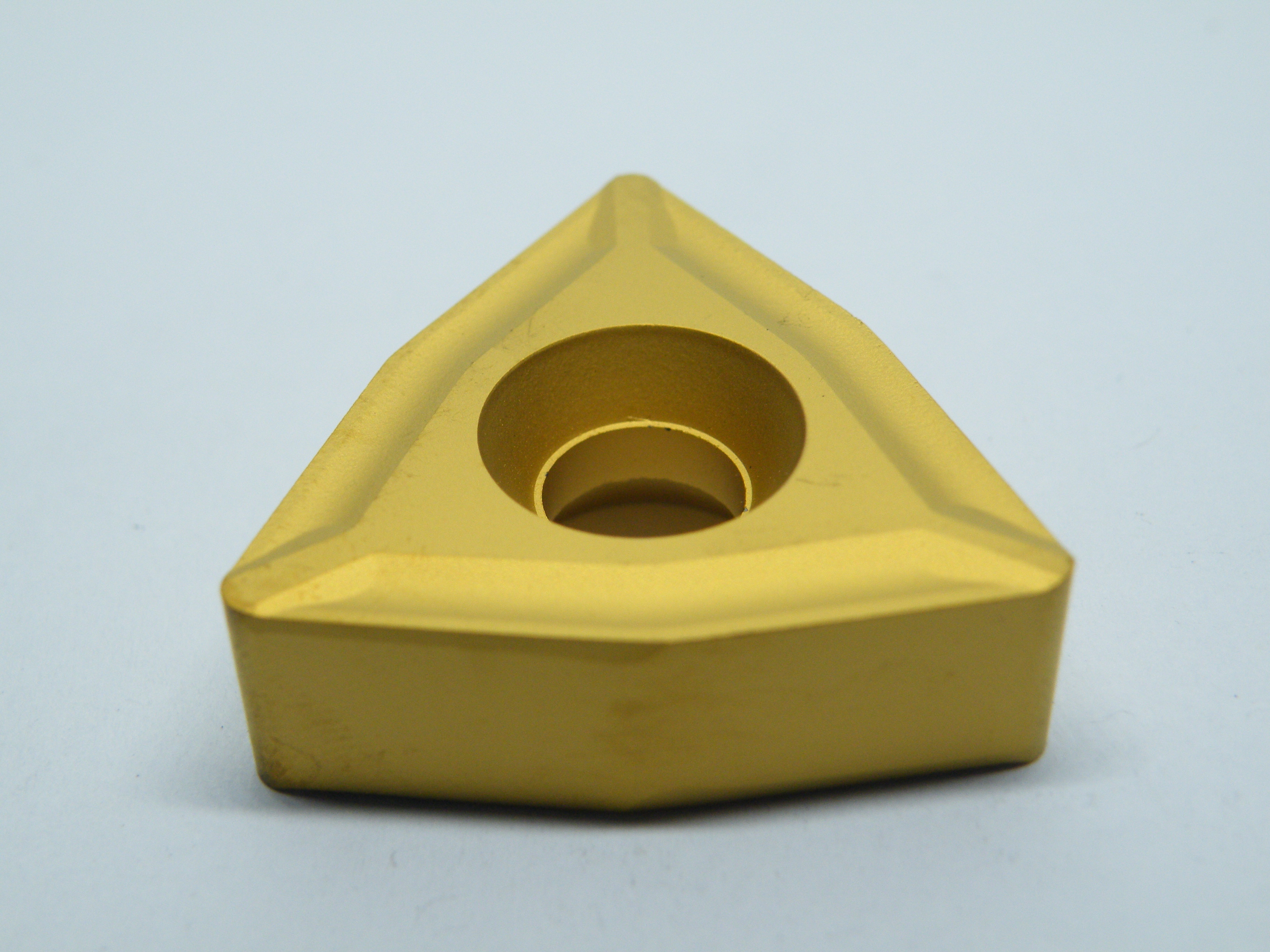

Corrosion Resistant Tungsten Carbide Inserts For External Turning

Tool

Products Introduction

CNC blade is main made from carbide tungsten, Co and TaC grain.

Environmental protection, high efficiency, energy saving,

recyclable. It is resistance high temperature, durable, corrosion

resistant and high strength, superior to traditional HSS. Carbide

woodturning cutter is widely used in handwork and lathe work.

Products Advantage

1. Replacement cutter to reduce the frequency of replacing blades

with longest working life.

2. Environmental protection, high efficiency, energy saving,

recyclable.

3. Complete specifications for choose in stock.

4. Easy to operate and easy to use.

VKD has plenty of chip breakers to choose which cover the

application range from steel, iron cast, stainless steel, aluminum,

heat resistant alloy, etc. Those chip breakers can replace the

relative ones of , KORLOY, TAEGUTEC, MITSUBISHI, SUMITOMO,

TUNGALOY, KROCERA, DIJET, ISCAR etc. DON'T HESITATE TO CONTACT

SUPPLER TO GET MORE DETAILS!

Chip breaker System

| | | |

| | Double sided chip breaker for medium machining. Wide range of

application in steel and cast iron. | (PM) |

| | Double sided chip breaker with good chip control. Suitable for

finishing and medium machining of steel and cast iron. | (-PF), SECO(-MF1) |

| | Double sided chip breaker for medium machining. Wide range of

application due to excellent balance of sharpness and cutting edge

stability. | (PM), SECO(MF2), KYOCERA(HQ) |

| | Double sided chip breaker with positive rake angle and stable

cutting edge for light to medium roughing of steel and cast iron. | |

| | Double sided chip breaker with good chip control. Suitable for

finishing and medium machining of steel and cast iron. | KYOCERA(-CF) |

| | Double sided chip breaker with sharp cutting edge and large rake

angle. Process reliable medium machining of stainless steel. | TUNGALOY(TM) |

| | Double sided chip breaker with large rake angle for low cutting

forces. Suitable for roughing of stainless steel. | |

| | Single sided chipbreaker for machining of cast aluminium alloys.

Sharp cutting edge with positive rake angle. G-tolerance for high

repeatability. | KORLOY(AR) |

| | Single sided chip breaker with excellent cutting edge design. Sharp

cutting edge with positive rake angle. G-tolerance for | KORLOY(AK) |

| | Single sided chip breaker with good chip control. Suitable for

finishing to medium machining of steel and cast iron. | MITSUBISHI(FJ,FV), KYOCERA(CF) |

| | Single sided chip breaker for medium machining. Wide range of

application due to excellent balance of sharpness and cutting edge

stability. | MITSUBISHI(FJ,FV), KYOCERA(CF) |

| | Single sided chip breaker with positive rake angle and stable

cutting edge for light to medium roughing of steel and cast iron. | |

| | Double sided chip breaker with surrounding cutting edge. Process

reliable machining due to highest cutting edge stability. | |

... | ... | DON'T HESITATE TO CONTACT US TO GET MORE DETAILS! | ... |

No. | Grade | Grade description | Grade(Competitors) |

1 | YBC152 | CVD coated P10–P20 carbide grade for finishing to medium operation

of steel and casting steel. Outstanding performance under higher

cutting speed and temperature with excellent wear resistance. | GC4315(), E6020(MITSUBISHI), T9125(TUNGALOY) |

2 | YB6315 | CVD coating grade combining nano dioxygen gradient transition

techniques and crystal nucleus pre-insertion techniques. | GC4315(), T9115(TUNGALOY) |

3 | YBC252 | CVD coated P20–P35 carbide grade for medium operation to roughing

of steel and casting steel. Optimal performance of wear resistance

and toughness for a wide application field. | GC4325(),E6020(MITSUBISHI),T9125(TUNGALOY) |

4 | YBD102 | CVD coated K05–K20 carbide substrate. Optimized for medium

operation of cast iron, special nodular cast iron and hard steel at

high cutting speed. | UC5115(MITSUBISHI) |

5 | YBD152 | CVD coated K10–K25 carbide substrate. Optimized for medium to

roughing operation of cast iron. Good wear resistance and toughness

at higher cutting speed. | UC5115(MITSUBISHI) |

6 | YBD152C | Thick Al2O3 CVD coated K05–K25 carbide substrate. Optimized for

medium to roughing operation of cast iron.Higher wear resistance

and toughness at higher cutting speed in combination with TC chip

breaker. | UC5115(MITSUBISHI) |

7 | YB7315 | CVD coated K10–K25 carbide substrate. Optimized for medium to

roughing operation of cast iron. Improved wear resistance and

toughness at high cutting speed. | UC5115(MITSUBISHI), WAK20() |

8 | YBM153 | CVD coated M10–M25 carbide grade for fnishing to medium application

in stainless steel. High wear resistance and capability against

plasctic deformation at higher cutting speed. | |

9 | YBM253 | CVD coated M15–M35 carbide grade for medium to roughing operation

in stainless steel with wide application field. High wear

resistance and capability against plasctic deformation at higher

cutting speed. | |

10 | YBG202 | PVD coated M10–M25/P10–P30 carbide substrate for finishing to

medium application of stainless steel and steel (milling). Good

wear resistance in a wide application field. | |

11 | YBG205 | PVD multilayer coated M20–M40/S15–S25/P10–P30 carbide substrate for

finishing to medium application of stainless steel, super alloy and

steel (milling). Good wear resistance and thermal stability in a

wide application field. | VP15TF(MITSUBISHI) |

12 | YB9320 | PVD multilayer coated M10–M25/P10–P30 carbide substrate for

finishing to medium application of stainless steel, super alloy and

steel (grooving/milling).Optimized coating stability for higher

wear resistance and thermal stability in a wide application field. | |

13 | YNT251 | Uncoated P10–P25 cermet grade for fine finishing to medium

operation of steel and stainless steel. Good wear resistance and

toughness. Suitable also in light interrupted cut. | |

... | ... | DON'T HESITATE TO CONTACT US TO GET MORE DETAILS! | ... |

Welcome your inquiry.